Columbia Machine Works machined this crankshaft for a mechanical stamping press

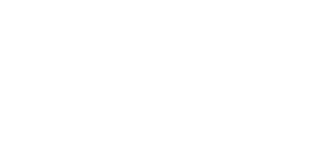

Stamping Press Emergency Repair

Columbia Machine Works worked around the clock to repair a die cushion assembly for a large OEM automotive customer. Pictured is the barrel component of the assembly being welded-up.

Repairing Connecting Rod for Stamping Press

Columbia Machine Works technicians discovered a crack in the bore for the rod’s wrist pin. We machined the old ‘knuckle end’ off, and machined dowel pin holes into the rod. We then fabricated a new ‘knuckle end,’ fitted the new part into the rod using dowels, and welded the assembly together. We then machined the newly-formed part back into spec. …

80,000 Pound Bolster Plate Machining

Columbia Machine Works machined this 80,000 pound bolster plate for a stamping press. We have the crane capacity to handle projects up to 50 tons.

Crankshaft Repair for Stamping Equipment

Columbia Machine Works checked this large stamping press crankshaft for signs of cracks and wear, and made necessary repairs in-house.

Machining 35,000 Pound Stamping Press Bolster Plate

Columbia Machine Works machining a 35,000 pound, 12′ x 8′ bolster plate for a stamping press.

Large Stamping Press Repair Service

Columbia Machine Works performed service on these large stamping press components.

Repairing Large Stamping Component

Columbia Machine Works utilized the capacity and capability of its new floor-type CNC horizontal boring mill to repair this sizable stamping press component.

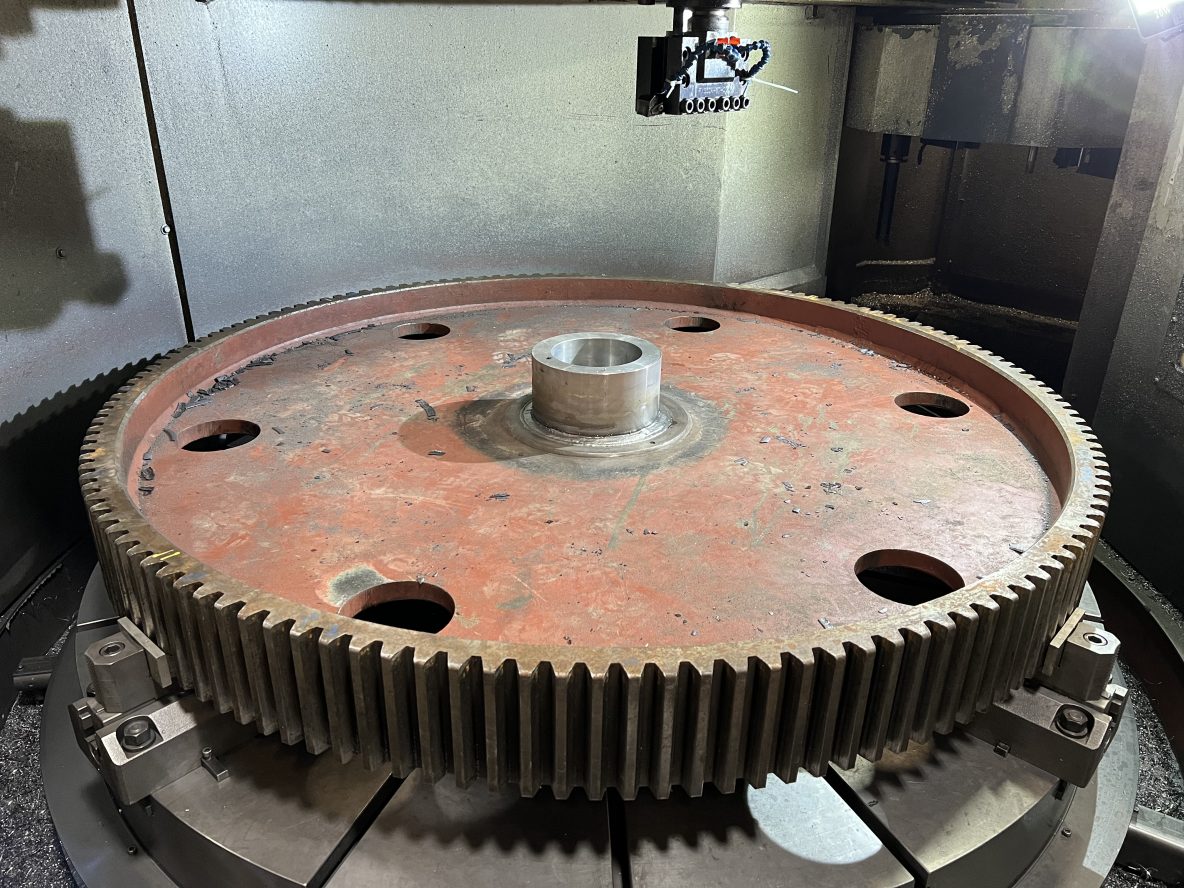

Machining 6′ Gear on CNC VTL

Columbia Machine Works machined this 72″ gear on our CNC vertical turning lathe

Machining Large Bolster Plate on CNC Floor-Type Boring Mill

Modifying a bolster plate on our newest CNC boring mill. Credit W7thCo for the photo.