Columbia Machine Works has the capability to roll plate into large-diameter shapes and forms.

Repairing Field Machinery

Columbia Machine Works inspected and restored the structural integrity of this piece of field machinery. Large fabrication work is one of our specialties.

Machining Large Weldment

Columbia Machine Works machined this large weldment on our largest CNC horizontal boring mill. This was fabricated in-house.

Fabricated Pneumatic Assemblies

Pictured is one of a set of pneumatically-operated assemblies CMW fabricated and tested in-house for one of our customers.

Connecting Rod Fabrication

Columbia Machine Works fabricated and machined this stamping press connecting rod from stock material to get a stamping customer back into production quickly.

Scrap Tub Modification

Columbia Machine Works is assisting in improving the design and function of these scrap tubs via an actuator system which will take the place of the existing manually-operated process. In addition, we rebuilt the chute doors to get them back in parallel. This design will not only be an improvement on the efficiency of the system, but more importantly the …

Fabricating and Machining Two Large Rings

Columbia Machine Works was contracted to fabricate two 11′ diameter rings. These rings were burned out on our CNC plasma table out of two pieces of 2″ A36 plate, then welded at the seams with 100% joint penetration. They were then put on the boring mill to receive 40 equally-spaced, drilled and counterbored holes around the full diameter. Then we …

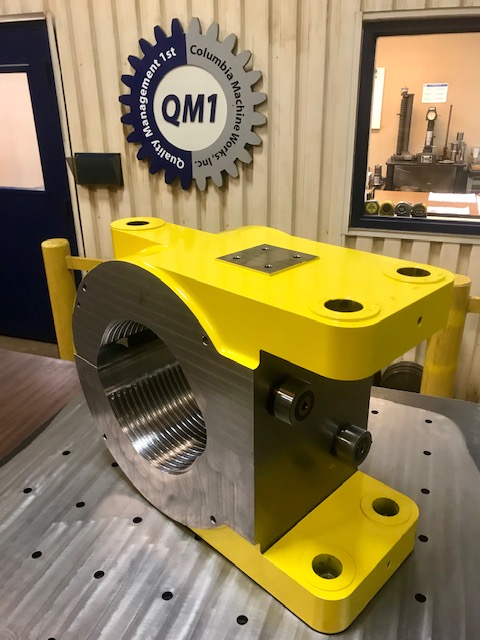

Fabricated Replacement Component for Die Casting Machine

On a nearly daily basis, we receive requests from customers to fabricate replacement parts for their machinery that are impossible to still get from the OEM. In these cases, all Columbia Machine Works has to work with, so to speak, is the broken piece of equipment that the customer ships to us and asks “can you make this?” Pictured below …

Emergency Press Repair Work for Automotive Stamping Customer

Our customer had a critical-to-production die with a crack in it, which was only going to get worse if something wasn’t done quickly. On the other hand, our customer could not afford to have their press out of service for more than a few days (was costing them millions of dollars per day to be out of service). So, over …