CMW turned the arms on this large rock crusher in one of its heavy-duty lathes. Our machining capacity is one of the largest in our area.

Large Stainless Steel Fabrication

Pictured is a large stainless steel fabrication being given a final quality inspection.

Machining Disk on CNC Horizontal Boring Mill

A large disk being machined on large CNC boring mill after being turned on our Vertical Turning Lathe.

Metallizing Shaft for Bearing Fit

Pictured is a shaft CMW metallized and turned for the purposes of ensuring a proper bearing fit. We have this capability for all sizes of components.

Repaired Tie Bar with Newly-Machined Head

This is a tie bar CMW repaired in its fabrication shop. The head for this tie bar was machined new by CMW and the shaft itself turned on one of our CNC lathes.

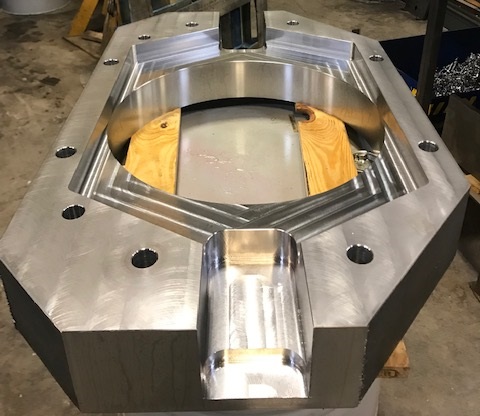

Precision-Machined Die Cast Component

CMW has many years of experience machining precise die cast replacement parts such as this dogleg piece for a 3000 ton die cast linkage.

Machining Eccentric Shaft for Stamping Machine

This is an eccentric shaft CMW machined out of stock material.

Precision Die Cast Component

Pictured is a precision die cast component CMW machined on one of its CNC machining centers.

Block Machining on CNC Boring Mill

These are a set blocks that CMW precision-machined on one of its CNC boring mills.