Columbia Machine Works has many years of experience in repairing, maintaining, and refurbishing stamping presses. We have a dedicated facility for repairs and field crews available for on-site maintenance.

Stamping Press Crankshaft Machining

Columbia Machine Works machined this crankshaft from scratch for a large stamping press.

Machining Adjusting Screw for Stamping Press

Columbia Machine Works machined this adjusting screw out of a stamping press to restore it to normal working order for the customer.

Fabricating Replacement Adjustment Screw for Stamping Press

Columbia Machine Works fabricated a replacement adjustment screw (pictured on the right) using the sample of the old part for a stamping press.

Fitting Stamping Press Crankshaft into Crown

CMW Technicians setting a crankshaft for a stamping press into the press crown.

Machining New Stamping Press Bolster Plate

Columbia Machine Works machined a new bolster plate for one of its stamping customers on one of our Haas VF-6 CNC vertical machining centers.

Machining Surfaces on Stamping Press Component

Columbia Machine Works machined the surfaces on this stamping press component to “clean-up,” ensuring the surfaces were suitable for accommodating other machined parts that fit into the press assembly. We are dedicated to finding the most effective repair for your press, from both a production and cost standpoint, in the most time sensitive manner possible.

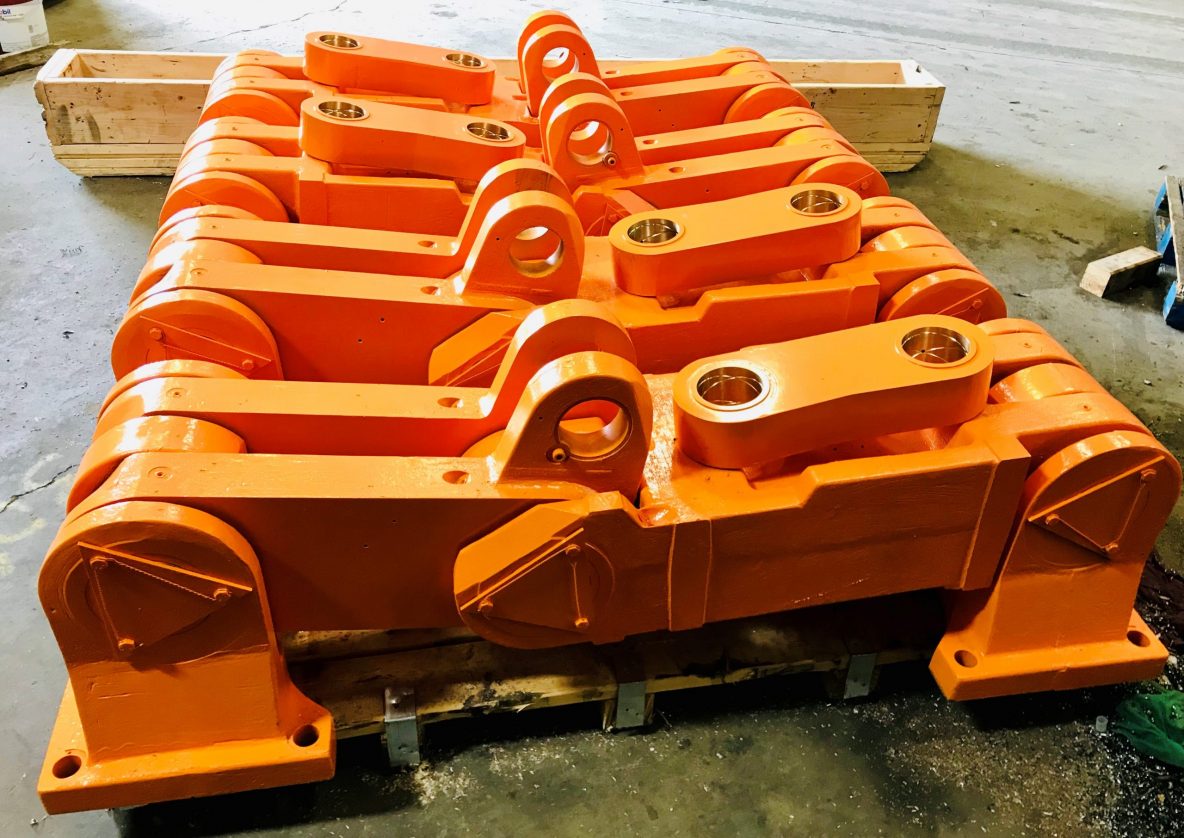

Die Casting Machine Linkage Repair and Rebuild

Columbia Machine Works rebuilt this linkage for a die casting machine. The linkage was first disassembled, cleaned, and inspected. We then removed all of the bushings and line-bored the linkage bores to bring them back to spec. New pins and bushings were machined to match the bores, then the linkage was re-assembled and painted. Die casting and injection molding machinery …

Repairing Field Machinery

Columbia Machine Works inspected and restored the structural integrity of this piece of field machinery. Large fabrication work is one of our specialties.

Machining Large Tie Bar From an Injection Molding Machine

Columbia Machine Works made repairs to this tie bar and then machined it in our largest CNC lathe.