Columbia Machine Works performed service on these large stamping press components.

Repairing Large Stamping Component

Columbia Machine Works utilized the capacity and capability of its new floor-type CNC horizontal boring mill to repair this sizable stamping press component.

Machining New Die Casting Machine Component

Columbia Machine Works machined this die casting machine component per OEM print specs. We have the capability to repair and rebuild all models and sizes of die casting machines, with the added ability to make new components per OEM spec for difficult-to-source and obsolete parts.

Excavation Bucket Repair

Columbia Machine Works repaired this large excavation bucket back to OEM spec.

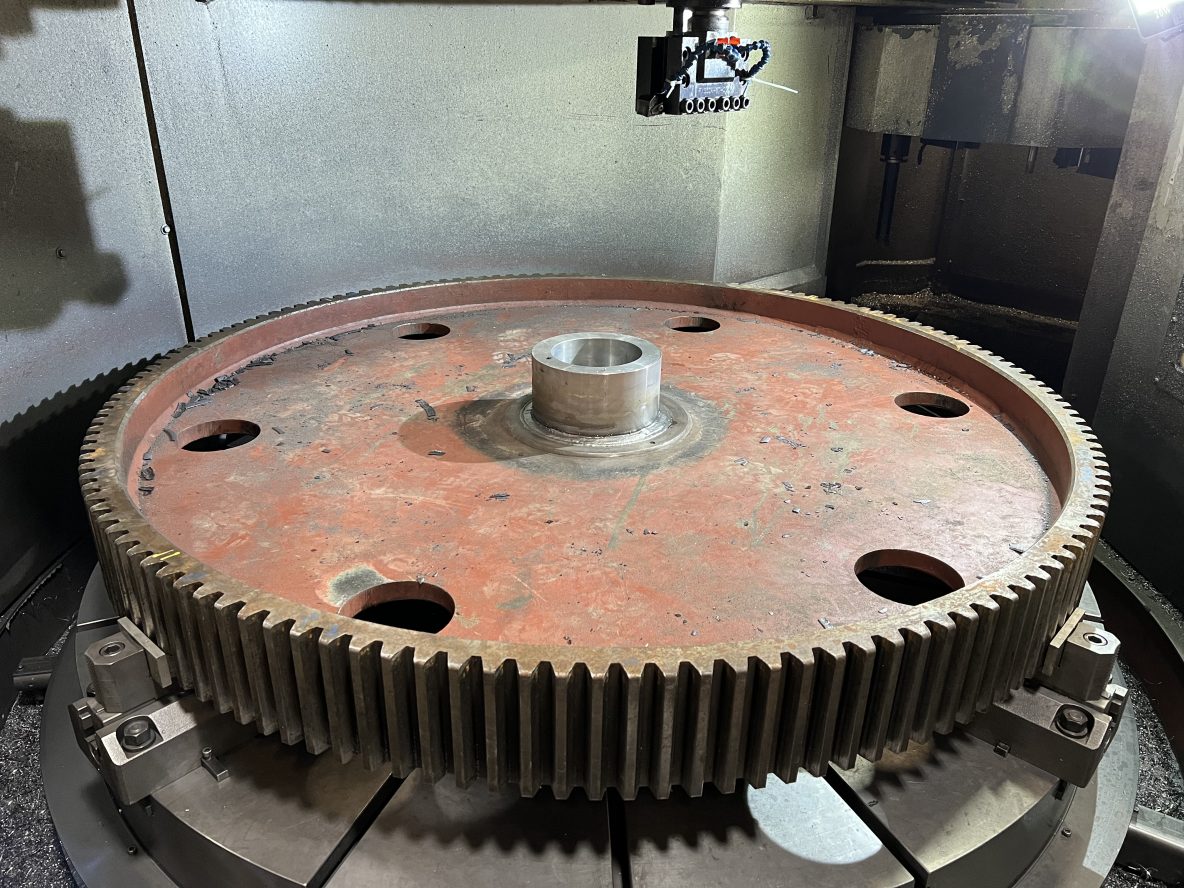

Machining 6′ Gear on CNC VTL

Columbia Machine Works machined this 72″ gear on our CNC vertical turning lathe

Machining Large Bolster Plate on CNC Floor-Type Boring Mill

Modifying a bolster plate on our newest CNC boring mill. Credit W7thCo for the photo.

Machining Stamping Press Ram

Columbia Machine Works machined this ram off of a mechanical stamping press

Die Cast Machine Tie Bar Repair and Machining

Columbia Machine Works repaired and re-machined this die cast machine tie bar. This was a more than 20′ long bar.

Crankshaft Shaft Machining

Columbia Machine Works machined this crankshaft for a mechanical stamping press from scratch.

Machining Stamping Press Frame

Machining a stamping press frame on a CNC horizontal table-type boring mill