Columbia Machine Works made repairs to this tie bar and then machined it in our largest CNC lathe.

Refurbishing 15″ Diameter Tie Bar for a Die Casting Machine

Pictured is one of the larger size of tie bars (15″ diameter) that we refurbish in our largest CNC lathe. Everything you see in this photo was machined new by Columbia Machine Works onto an existing tie bar that had broken. New tie bars, as well as most any die casting or injection molding machine components, are expensive to replace. …

Line Boring Die Casting Machine Linkage Pin Holes

Columbia Machine Works repaired the linkages for these die casting machine platens. We cleaned up the bores, made new bushings and pins, and re-assembled the linkage to get it back in the proper working order.

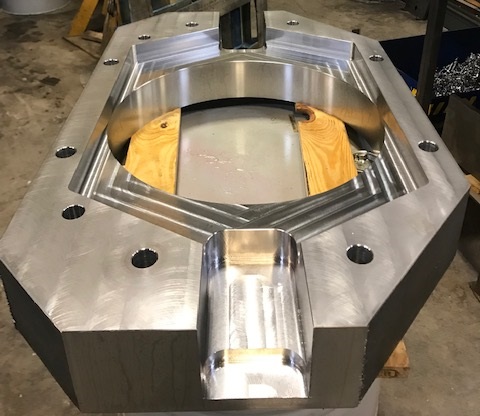

Repairing an Ejector Plate for a Die Casting Machine

Columbia Machine Works repaired this ejector plate for a die casting machine. The first step was to grind the cracks out of the plate and weld them up. We then machined the closing cylinder mounting surfaces, ensuring that any welding on the cracked cylinder mounting holes were machined out. Pictured here, the next step was line boring the guide rod …

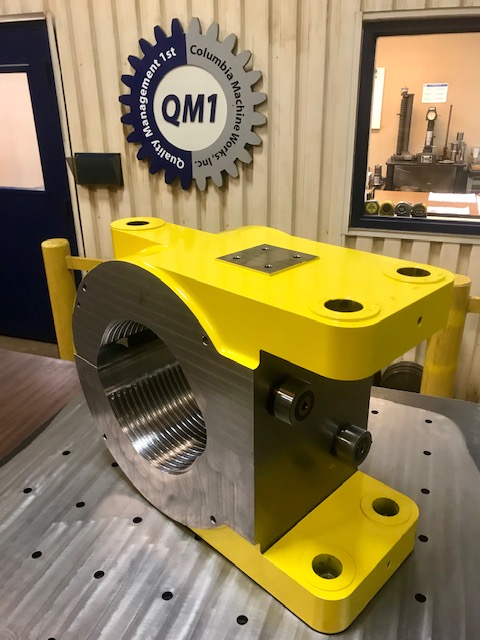

Fabricated Replacement Component for Die Casting Machine

On a nearly daily basis, we receive requests from customers to fabricate replacement parts for their machinery that are impossible to still get from the OEM. In these cases, all Columbia Machine Works has to work with, so to speak, is the broken piece of equipment that the customer ships to us and asks “can you make this?” Pictured below …

Repaired Tie Bar with Newly-Machined Head

This is a tie bar CMW repaired in its fabrication shop. The head for this tie bar was machined new by CMW and the shaft itself turned on one of our CNC lathes.

Precision-Machined Die Cast Component

CMW has many years of experience machining precise die cast replacement parts such as this dogleg piece for a 3000 ton die cast linkage.

Precision Die Cast Component

Pictured is a precision die cast component CMW machined on one of its CNC machining centers.

Tie Bar Adjusting Nuts

Pictured is set of tie bar adjusting nuts that CMW machined out of stock material. We have many years of experience in all facets of tie bar repair and machining.

Die Casting Component Fabrication

Pictured is a cylinder CMW fabricated complete for a die casting machine.